Science Meets Beauty

Our cosmetics research and production services focus on innovation and quality, offering cutting-edge formulations tailored to meet diverse skincare and beauty needs. From product development to manufacturing, we ensure premium solutions that combine effectiveness, sustainability, and the latest advancements in cosmetic science.

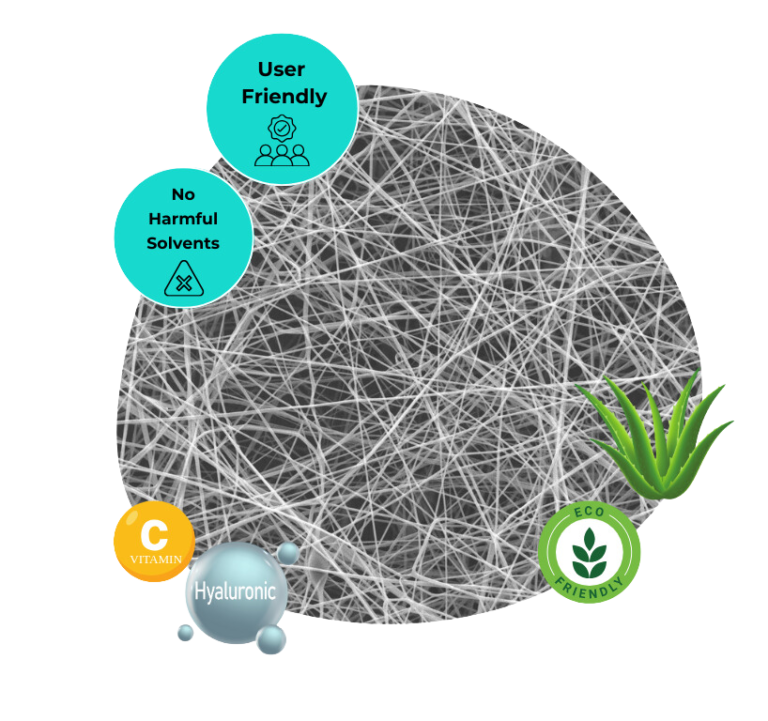

Why Nanofibers in Cosmetics?

High Surface Area-Lightweight

Nanofibers have a significantly higher surface area compared to conventional fibers. This allows for better absorption and retention of cosmetic ingredients, such as moisturizers, serums, or active compounds, enhancing their effectiveness. More contact with the skin.

Dry Form-No Ingredient Loose

The ultrafine nature of nano fibers enables them to conform closely to the contours of the face, providing better adherence and contact with the skin. This ensures that the cosmetic ingredients are delivered evenly and efficiently, maximizing their benefits. Dry sheet form- no ingredient loose while applying.

Flexible Configurations,

Nano fibers can be engineered from biocompatible materials, reducing the risk of skin irritation or allergic reactions. This makes them suitable for use in cosmetic products, even for individuals with sensitive skin.

Immediate Absorption

When nanofibers are applied to a slightly moist area of the skin, they are absorbed by the skin within seconds.

Nanofiber Dry Sheet Masks

- Easy penetration to deeper skin tissues due to nanoscaled ingredients.

- Easy to work with Non-toxic solvents.

- Long lasting healing on skin due to the more contact points.

- Pure vitamins and active ingredients without any chemical contamination.

- Overcome degradation.

- All ingredients are transferred to the skin during application.

- Nanoparticles

- Hyaluronic Acid

- Collagen

- Vitamins

- Natural Extracts

- Antioxidants

- Ceramides

- Pepdites

What we offer?

Plasmagear has both lab-scale industrial electrospinning machine where 1.6 m in width a hundreds meters of rolls can be produced.

1

Research and Development Projects

Turning an idea into a Target Cosmetic Product Profile including technical feasibility and IP considerations, bearable pricing and risks.

2

Contract Manufacturing

Tailored manufacturing solutions that adhere to both research-grade and commercial-grade standards. Our contracts are built upon the specific product requirements and supply terms outlined by the client.

3

Product Production

Plasmagear offers selling rolls of nanofibers to be used in cosmetic industry (no final product).