High-Performance

PFAS-Free Textile Solutions

We offer a cutting-edge, PFAS-Free hydrophobic coating for textiles, utilizing advanced plasma technology as an environmentally responsible alternative. This innovative treatment provides long-lasting and highly effective water resistance, significantly enhancing the durability and performance of fabric surfaces. By eliminating the use of harmful PFAS chemicals, our solution not only ensures safer textiles but also contributes to a more sustainable approach.

The waterless nature of our treatment process preserves the fabric’s original color, texture, and comfort, ensuring that the aesthetic qualities and wearability of the textile are maintained. This eco-friendly hydrophobic treatment offers superior protection while aligning with a commitment to environmental stewardship and consumer well-being.

Why Choose Our Nanofiber-Coated Fabrics?

- Water Resistance with Breathability

Our nanofiber-coated fabrics are engineered to resist water while allowing air to pass through. This balance ensures comfort without compromising on protection.

- Fire Resistance

With plasma coating and nanofiber layers, our fabrics offer exceptional heat resistance, making them ideal for high-performance and extreme conditions.

- Enhanced Durability

The advanced nanofiber layers strengthen the fabric while ensuring it remains lightweight and durable over time.

- Sustainable and Eco-Friendly

With the growing demand for environmentally friendly products, our nanofiber solutions align with sustainability goals by offering PFAS-free water resistance for safer alternatives and utilizing low-energy plasma processing to minimize environmental impact during production.

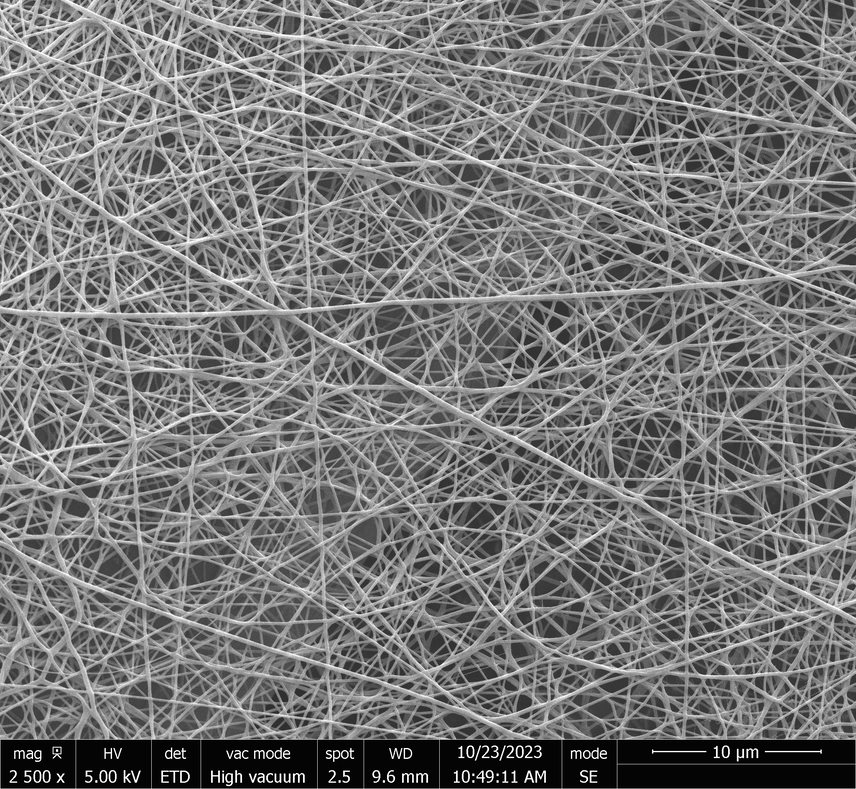

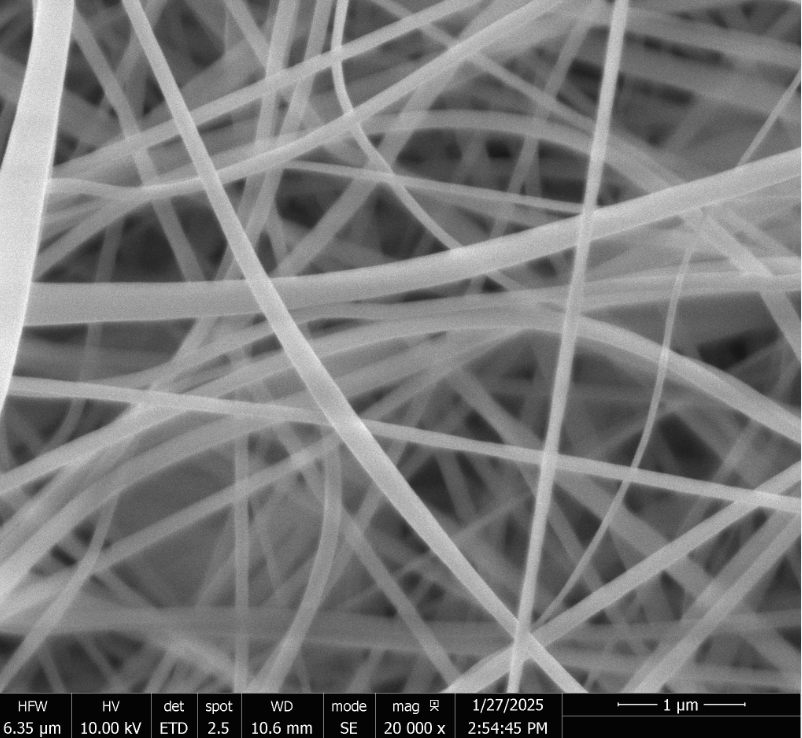

Use of nanofibers in textiles

Nanofibers are ultra-thin fibers with a diameter measured in nanometers. Their unique structure allows them to provide:

- Superior filtration and protective properties

- High surface area for enhanced functionality

key performance parameters of our advanced fabrics

1

Tailored Water Resistance

Our plasma-engineered water resistance creates breathable, eco-friendly fabrics without harmful fluorine-based coatings, perfect for outdoor and protective gear.

2

Breathable Comfort for Active Performance

Our fabrics provide superior comfort by maintaining breathability, even during sweating. The moisture can escape while the water is blocked from penetrating, making you feel comfortable and dry in all conditions.

3

Fire Resistance

Our fabrics combine fire retardancy with high particle capture. They resist flames while trapping harmful fire particles, providing enhanced safety and protection in high-risk environments.

4

Enhanced Durability

Nanofiber-coated fabrics are built to last, withstanding washing, wear, and exposure to harsh conditions.

Superior Protection for High-Risk Applications

PFAS-free Flame-Resistant Nanofiber Technology

Our flame-resistant (FR) membranes are engineered to provide maximum fire protection, durability, and performance in various industries. Designed with cutting-edge nanofiber and plasma technology, our membranes offer fire resistance, breathability, and waterproof properties while maintaining flexibility and comfort.

- Exceptional Fire & Heat Resistance

- Waterproof & Breathable

- Chemical & Mechanical Durability

- Lightweight & Flexible

- Customizable Solutions

Innovation, Performance, Market Readiness

- Scalable Electrospinning

Solving large-scale production challenges.

- Proprietary Innovation

Protecting our breakthrough FR nanofiber technology.

- Unmatched Filtration Efficiency

Maximum protection with nanofiber-microfiber design.

- Regulatory Compliance

Meeting industry standards and evolving safety needs.

Applications

Military gear

Durable and functional clothing and equipment designed for military personnel. These are typically built to withstand harsh conditions, offering protective qualities and optimized for performance in combat situations.

Firefighter suits

Specially designed clothing for personnel fighting fires, built to withstand high temperatures and offer protective features. These suits help regulate body temperature and protect against flammable materials.

Industrial workwear

Protective clothing designed for workers in industrial environments, safeguarding them from potential hazards such as heavy machinery, chemicals, or temperature fluctuations. These garments are tailored to ensure safety in dangerous work settings

Key Requirements in a FR Membrane

- Fire Retardancy

- Sustainable (PFAS-free)

- High Filtration Efficiency

- Thermal Resistance

- Thermal Load and Breathability

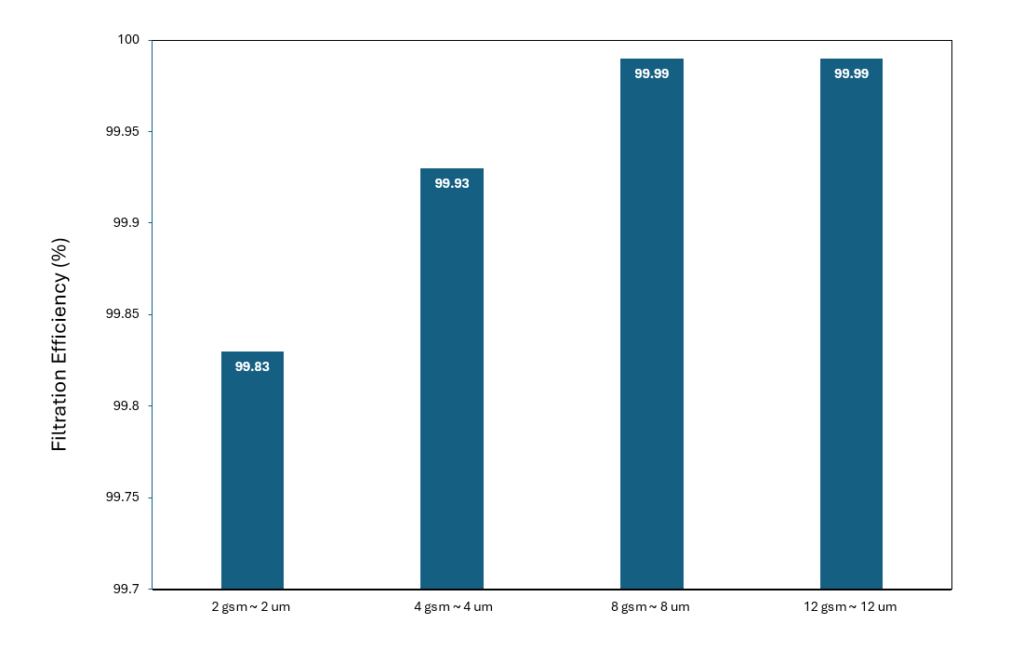

We Tailor Filtration Efficiency Through Structural Engineering

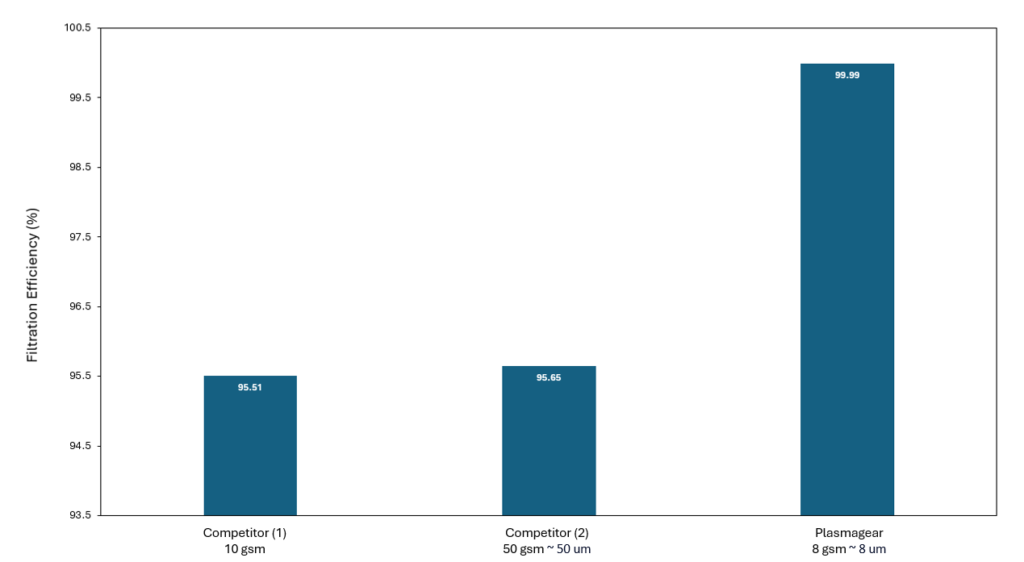

Benchmarking Competitor Performance:

Strengths & Limitations

Competitors sacrifice ~5% filtration efficiency to improve breathability, compromising protection against hazardous particles.

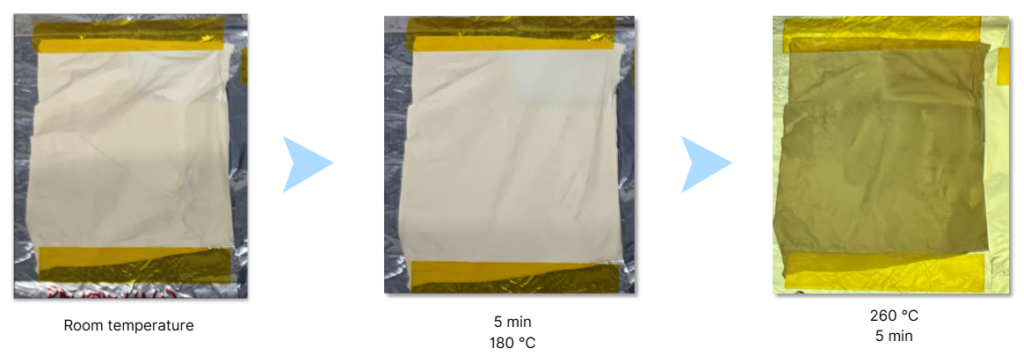

No Melting, No Degradation!

Nanofibers Durability Under High Temperatures

Why Choose Nanofiber Technology?

1

Exceptional Filtration Efficiency

Nanofibers offer an unparalleled filtration efficiency, capturing up to 99.9% of hazardous particles, including ultrafine contaminants and fire-related particulates. This high level of performance ensures that nanofiber-based filters provide superior protection in various applications, ranging from industrial safety gear to air filtration systems.

2

Lightweight and Thin Construction

One of the key advantages of nanofiber technology is its lightweight and ultra-thin design. Despite its high filtration capabilities, nanofiber materials do not add significant bulk, allowing for the production of protective gear that offers enhanced comfort and flexibility. This characteristic makes them ideal for applications where user mobility and comfort are essential, without compromising on safety.

3

Customizable Properties for Tailored Solutions

Nanofiber materials can be precisely engineered to meet specific requirements. The composition, fiber diameter, porosity, and layering of nanofiber-based structures can be adjusted to optimize performance for a wide range of applications. This flexibility allows manufacturers to create bespoke solutions that cater to unique industrial, environmental, or safety standards.